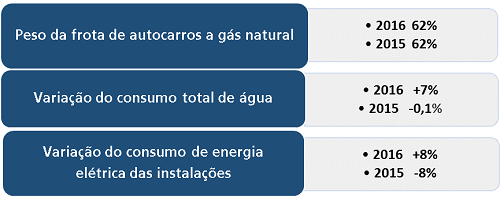

Certified SINCE 2008STCP was the first urban public transport company in Portugal to have a Certified Integrated Management System, simultaneously, by three normative references: • NP EN ISO 9001:2008 – Quality Management Systems • NP EN ISO 14001:2004 – Environmental Management Systems • ISO 45001: Occupational health and safety management systems (previously OHSAS 18001:2007 / NP 4397:2008) All activities and facilities of STCP, with the exception of the Tramcar Museum, are covered by the scope of the Certifications, including the provision of the service itself, the maintenance of vehicles and customer service. The Certifications integrated STCP in a vanguard group of companies, distinguishing it from other transport operators, which is internally an additional factor of motivation and pride for all workers, though requiring a constantly active participation on the part of the workers. The Certifications are assigned for a period of three years, with annual monitoring audits by the Certifying Entity and were revalidated in 2016. THE STCP'S ENVIRONMENTAL POLICYSTCP'S ENVIRONMENTAL POLICY In the activity of collective road transport, STCP assumes a relevant role in the environmental quality of the urban space where it operates. The commitment to contribute to a better future leads the company to focus on continuous improvement, always looking for the most efficient and less harmful impacts of technological solutions, thus contributing to social and environmental sustainability. The signing in 2010 by STCP of the Charter of Sustainable Development of UITP (International Union of Public Transport), in its Full Charter version, is the clear proof of this commitment, thus attributing a greater level of responsibility and demand to the company.  In 2016, STCP consolidated its communication with regulators, in accordance with the legal regulations that regulate its activity in terms of environmental impact, namely through the monitoring of emission sources, control of the use of fluorinated gases with effect of greenhouse gas emissions and ozone layer depletion, effluent analysis and control and waste management. Evolution of some indicators:  FLEETThe company has been implementing multiple actions to reduce emissions of pollutants from vehicles, such as: the diversification of fuels used in the fleet, with the use of 54.5% of natural gas buses and the renewal of the fleet, replacing it with buses with an environmental performance progressively more efficient.

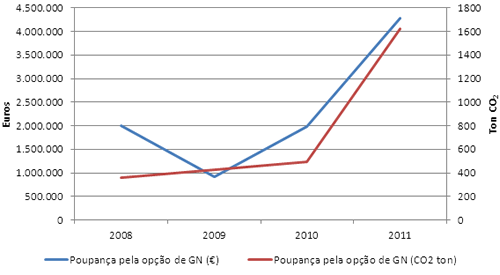

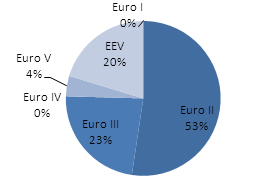

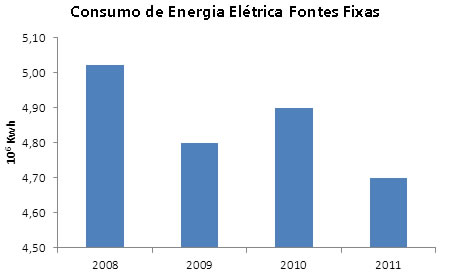

With the entry into operation of 15 vehicles of two floors and the slaughter of 36 diesel vehicles, the bus fleet was allocated as follows, in accordance with the energy sources: 54.5% of vehicles (255) natural gas and 46.5% of diesel vehicles (213). The option for natural gas fleet allowed the reduction of CO2 emissions in 1,626 tons and savings of approximately 4.3 million euros in 2011. Since 2001, the year of commencement of use of natural gas vehicles, energy-savings by diversification use of gas instead of diesel fuel – was about 18 million.  Replaced vehicles that meet the EURO I standard for vehicles that meet EURO V and EEV standards. About 25% of the fleet already complies with these standards, the most environmentally demanding in force in the European Union. These standards impose limits to emissions of nitrogen oxides (NOx), unburned hydrocarbons (HC) and particulate (PT), which are intrinsic to the emissions engine technology.  ENERGYWas elaborated a plan for rationalization of consumption of electric energy, implemented in the year 2011, with the goal of adapting effective needs of consumption activities of the company. In this context the review of all the official network of compressed air to eliminate leakage and to adapt to actual reductions and Officinal activity, which have been taking place. Settled also timers, allowing the power cut off the compressors of normal working hours.

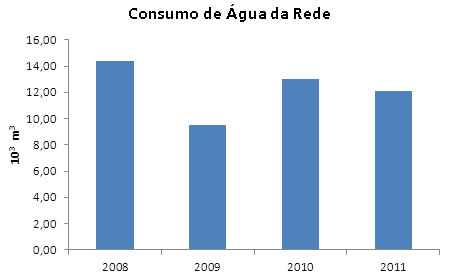

Circuit-breakers were triggered by installed counters and time switches for adjusting the lighting of car parks collection stations. In this way, between the 02:00 and the 05:00, the lighting of two stops was reduced by approximately 60%. Was still fixed the power factor of the collection Station of s. Roque. All these measures have contributed to a reduction of 4% in the consumption of electric power in stationary installations.  WATERThe water consumption decreased by 7% network (906-m3) because of awareness held for workers of the company and the adoption of good practice.

WASTE MANAGEMENTEnvironmental responsibility involves the rationalization of material consumption and the sustainable management of waste produced. STCP is a selective collection and conveyance of waste to the best destination, giving preference wherever possible its recovery.

Aiming to sensitize workers to the adoption of good practices in the selective separation of waste, gave up a teaching program that covered 117 workers and were distributed to all mini ecopoints premises.  In 2011 there was a decrease in the majority of waste produced, highlighting the reduction of metal waste by 71%.

In 2011 amounted to 16.4% recovery of waste generated, the quantity produced decreased by 27% and cost optimization with the proper selection and differentiated appropriately licensed waste operators. It is estimated cost reduction by 40% for 2012. With the optimization of waste management, environmental management policy STCP closes a cycle that began with the environmental certification, since all environmental aspects were the subject of a detailed analysis, and led the development of an environmental management plan, reviewed annually, continuous improvement, with the consequent optimization procedures, allowing achieve results that contribute to economic rationalization in sustainability. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||